Engineers Chalk: The Use of Soapstone in Welding

Probably one of the oldest if not the oldest fabrication process we know today is welding. It was done way before the industrial revolution made it more accessible and mainstream and it has now become the most efficient and reliable way of joining metal pieces. A welding joint is sturdy and can withstand high levels of heat before it starts to melt. The latter depends on the type of metal you're using.

But metal isn't the only material you can weld, wood and plastic can be welded too they just require a specific welding process to be carried out. With there being different welding processes and different materials that can be welded, you'd think most of the equipment would be different. Well, that may be the case for some pieces of equipment, for others not really. This is the case with welding chalk, or as they also call it engineer's chalk.

Soapstone

What is it?

You might consider yourself an engineer if you use soapstone but this sort of material doesn't make you one as its use goes beyond welding. This level of versatility is thanks to the way soapstone is formed. Soapstone develops at certain places on this planet of ours, these are mainly the edges of tectonic plates. This is where a process called metasomatism occurs. This process involves dry, reactive chemical fluids modifying siliceous dolostones with the result of that being the material used in the useful engineer chalk sticks welders praise nowadays.

Benefits

But why do welders like using soapstone or welding chalk as they call it? Soapstone is known to be unaffected by various physical changes such as high heat and pressure. Although soft and light, soapstone is able to leave a mark on any material without the mark being getting dusted off with your sleeve or other equipment. The only way you can get rid of a soapstone mark is to destroy the workpiece you have it on. You can see where I'm going here.

What is Soapstone Used for In Welding?

Cuts

Welders don't only join pies of metal together, with the right equipment they can also cut it. To ensure those cuts are as uniform and as straight as possible they use engineer chalk sticks to mark the area they need to cut. This way the cuts themselves are a lot easier to make since you have something to guide you without impeding your level of maneuverability. Also, the mark isn't visible afterwards since you've pulverised it by cutting the workpiece.

Marking

Another great use of engineer chalk for welders is when you need to mark a workpiece. While the mark will stay on no matter what, if the workpiece is going to be covered in paint at a later date you have nothing to worry about. No matter how hard you go at the workpiece, nothing will erase the marks you make. Be it measurements or just doodles they will stay on until either over by a layer of paint or duct tape.

Flame Straightening

Even the best of us have bad days in the shop and putting too much stress on a material can distort the weld. Mistakes are made every day so you try to counteract the distortion by inducing the heat on the opposite side of the joint. Well, in that case, you'd be happy to find out that soapstone can make things a lot easier for you. You can trace out the other side of the joint with engineer's chalk to transpose the dimension of the weld path to the other side. You won't have to do this on a piece of paper or try out other methods to straighten the flame and make a neat weld.

Other Ways to Mark Metal Surfaces

Markers

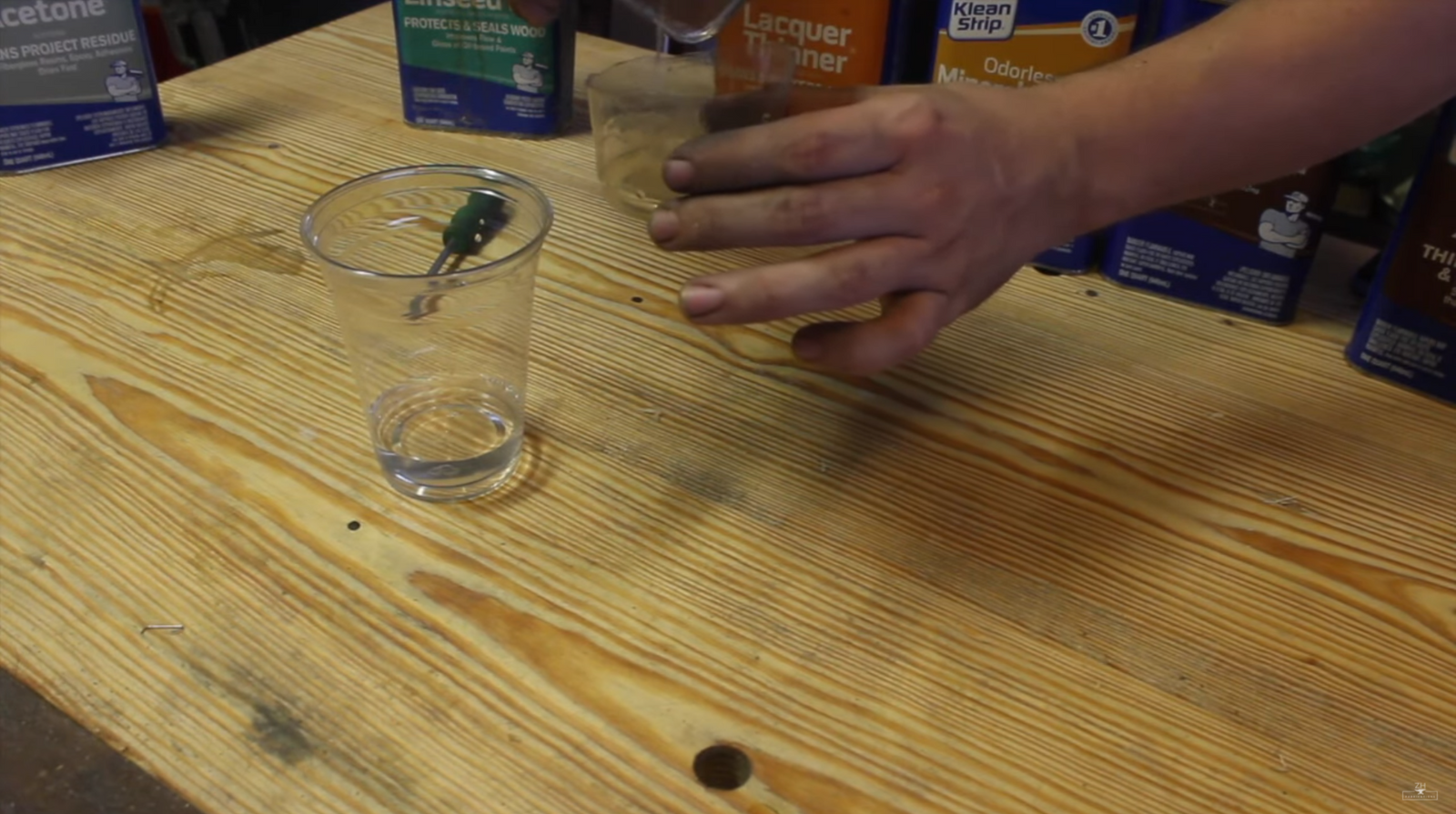

Although soapstone is one of the best solutions when it comes to marking workpieces ready to be welded people have taken other routes. A lot of welders have used permanent markers which despite being called permanent they are only capable of being permanent under certain conditions. High heat is sadly not one of those conditions.

Paint

While paint can be a bit tougher to remove from a metal workpiece than a permanent marker you still wouldn't want to use it. You can easily dissolve it with some paint thinner or just peel it off with some heat and a grouting tool.

Pens

I mean, you can use whatever you want to mark your workpieces with but using pens is something that even a kid would know not to do. No offence to people that have used a pen but it's just a waste of time. You're better off with a market, honestly.

Conclusion

It's safe to say that soapstone, no matter how malleable it can seem, is able to help welders correct their mistakes and prevent them from making future ones as much. Although making mistakes is part of the job by using soapstone you will avoid making major ones that are the ones you don't want to do. If you're serious about becoming a welder then having engineers chalk sticks with you is an inevitable part of the job.